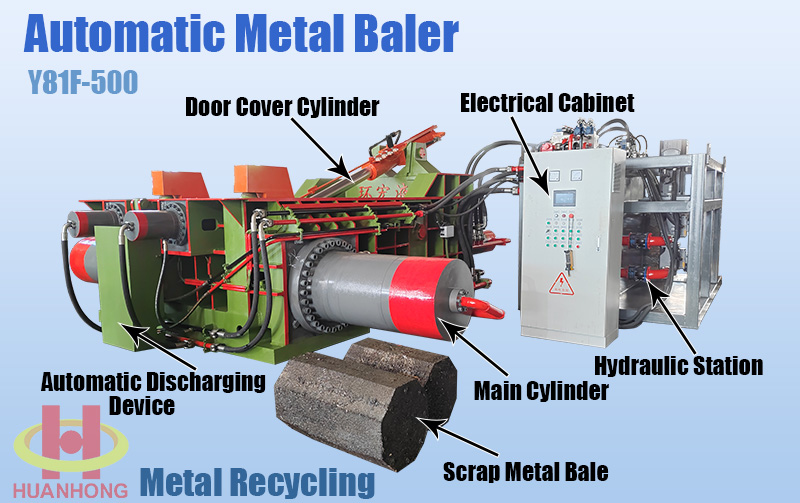

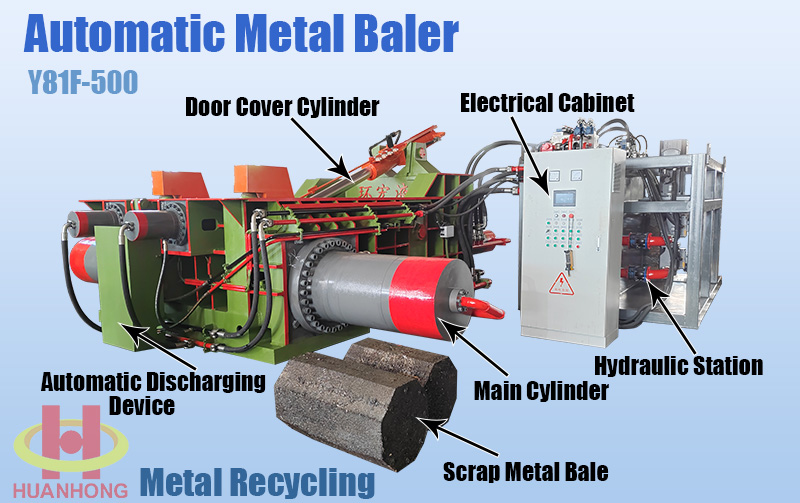

Introduction of scrap metal baler

This is a double-main-cylinder hydraulic metal baler designed for processing various metal scraps. This hydraulic metal baler mainly uses the hydraulic principle to press loose scrap metal materials into compact blocks through external force. The main cylinder pressure of this hydraulic metal baler is 5000KN, the material box size is 2000*1750*1000mm, and an automatic discharging device is designed to facilitate the collection of metal blocks. The blocks punched out by this hydraulic metal baler are octagonal, and the cross-sectional size of the blocks is 400*400mm on opposite sides. According to customer needs, the size of the material box and the size of the metal blocks of our metal balers can be customized. This Y81 series hydraulic metal baler has a variety of bag discharging methods. In addition to this forward-flipping bag discharging method, there are also conventional manual bag discharging methods and side-push bag discharging methods. The emergence of this hydraulic metal baler has improved the efficiency of scrap metal recycling, optimized green production, saved resources from the source, and played an important role in the scrap metal recycling industry, metal smelting industry, and automobile dismantling industry.

Advantages of scrap metal baler

·Reduced storage space: High-density, compacted metal blocks take up significantly less storage space, effectively saving floor space.

·Cost savings: Since the volume of the compressed scrap metal blocks is reduced, it can effectively reduce transportation costs.

·Environmental benefits: Improve recycling rates and reduce waste.

Safety: Modern balers are equipped with advanced safety features to protect operators.

Parameter of scrap metal baler

Model | Nominal Force | Material Box Size | Bale Sectional Size (Octagon) | Motor Power |

Y81F-500 | 5000 KN | 2000*1750*1000 mm | Opposite side 400*400 mm | 75 KW |

The above parameters are for reference only.

Applications of scrap metal baler

Y81 series hydraulic metal balers are mainly used in scrap metal processing and play an important role in scrap metal recycling centers, metal smelting industry, non-ferrous metal processing industry and scrap car dismantling industry.

For example, in the metal smelting industry, scrap metal balers are used to compress metal scraps into tight packages so that they can be easily fed into the furnace. This improves the efficiency of the smelting process and reduces the cost of raw materials.

In the non-ferrous metal processing industry, metals such as aluminum, copper and brass are usually more valuable and need to be handled carefully to maximize recycling efficiency. Hydraulic metal balers help to compress these materials into tight packages that can be sold at a higher price.