Introduction of the aluminium scrap baler

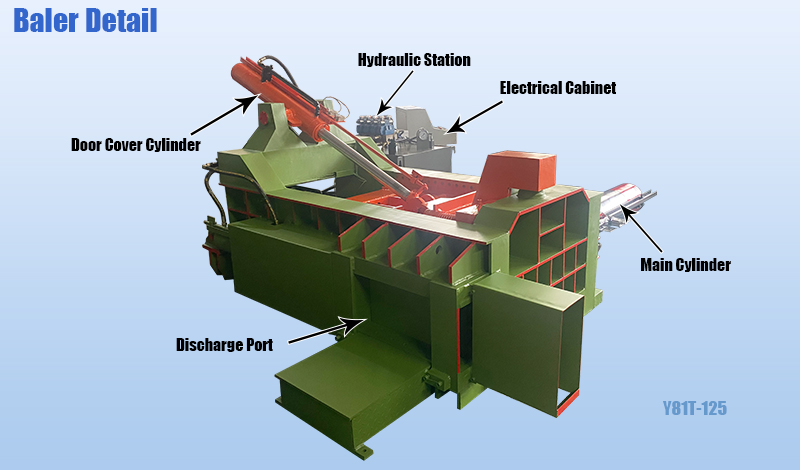

The Y81 series hydraulic metal baler is a highly efficient scrap metal processing machine specially designed for scrap metal recycling. This is a 125-ton Y81 series small hydraulic scrap metal baler with an automatic rollover device. This small hydraulic scrap metal baler is custom-made and is specially used for baling and compressing aluminum scrap, such as aluminum cans, aluminum chips, aluminum shavings, aluminum profiles, etc. Therefore, this hydraulic scrap metal baler can also be called an aluminum scrap baler, a hydraulic aluminum can baler, a hydraulic scrap aluminum baler, etc.

Advantages of the scrap metal baler

Small hydraulic metal balers can quickly and efficiently process scrap metal of various shapes and sizes. Compared with traditional manual baling, it reduces operating costs, improves production efficiency, avoids the dangers encountered by workers in the traditional baling process, and is safer. This hydraulic scrap metal baler is cold-pressed using the hydraulic principle. The metal bales produced are high in density, do not require adhesives, and do not change the properties of the metal. And according to the needs of different customers, the main cylinder compression force of the hydraulic scrap metal baler ranges from 63-4000 tons for customers to choose.

Technical specification of the aluminium scrap baler

Technical specification of Y81T-125 metal baler |

Model | Y81T-125 |

Nominal pressure(kn) | 1250 |

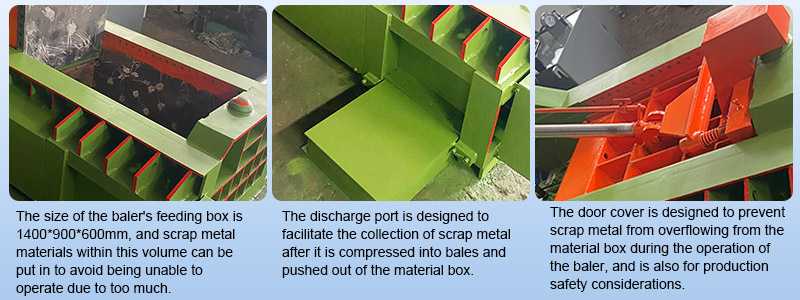

Bin size(L*W*H)(mm) | 1400*900*600 |

Bale size(W*H)(mm) | 300*500 |

Power(kw) | 15 |

Hydraulic system pressure(MPa) | 22 |

The above parameters are for reference only. The balers can be customized.

Applications of the aluminium scrap baler

Small scrap metal balers are widely used in metal recycling, steel and non-ferrous metal smelting, renewable resources, machining, etc. This metal baler is suitable for processing various types of metal waste, including non-ferrous metal waste, scrap steel, scrap aluminum, scrap copper, scrap stainless steel, scrapped cars, steel shavings, scrap iron, aluminum shavings, dismantled car shells and waste oil drums. After being processed by the small scrap metal baler, these scrap metals can be compressed into qualified furnace materials in various shapes such as cuboids and cylinders, which are convenient for storage, transportation and recycling.

Customized service

1. Material box size: Customers can customize suitable material boxes according to their own production needs.

2. Metal bale size: Customers can customize suitable bale shape and size according to subsequent processing needs.

3. Unloading method: Customers can choose unloading methods such as side flipping, front flipping, front push, side push, mechanical grabbing, etc. according to site requirements.

4. Machine power: In places without power supply, the hydraulic aluminum scrap metal baler can choose to use a diesel generator as power.

Aluminum Scrap Baler Frequently Asked Questions

Q1: What is the main function of the hydraulic scrap aluminum baler?

A1: The hydraulic scrap aluminum baler is mainly used to compress loose scrap aluminum into regular bales.

Q2: What are the unloading forms of the hydraulic scrap aluminum baler?

A2: The discharging forms of the hydraulic scrap aluminum baler include forward flipping, side flipping, forward push, side push or mechanical grabbing, etc., to adapt to different operating needs and environments.

Q3: What industries are hydraulic scrap aluminum balers used in?

A3: Hydraulic scrap aluminum balers are mainly used in recycling and processing industries, metal smelting industries, automobile dismantling centers, etc.

Q4: Can the hydraulic scrap aluminum baler be customized?

A4: Yes, the compression chamber size and packaging size of the hydraulic scrap aluminum baler can be customized.